Tel: +86 -13395690877

Email: nero@anhuibrush.com

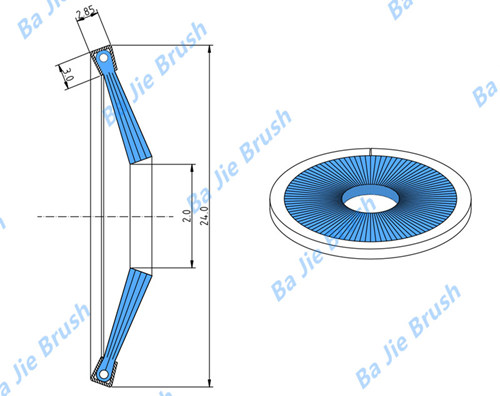

At Ba Jie Brush, we take pride in solving complex customer challenges through innovation and precision manufacturing. Recently, we partnered with Mr. M from Poland, a procurement manager for a fruit processing factory. He was searching for industrial brush components—specifically Inside Disk Brushes—to be used in Cherry and Plum Destoner machines for removing fruit pits.

The Client’s Requirements

Mr. M’s request was highly specific, tailored to the size and processing needs of cherries:

The requirements were driven by both fruit size compatibility and food safety regulations. Since cherries and plums contain natural acids, stainless steel was the ideal choice for corrosion resistance, while nylon filaments ensured compliance with food-contact standards.

The Challenge

Before approaching us, Mr. M had contacted nearly every brush factory in China. None could meet his demands due to two major difficulties:

Our Solution

Although this was also a new challenge for our factory, our team embraced the opportunity. After in-depth research, our technical department identified the key: improving the bending technique so that stainless steel could be formed precisely without deformation, while still holding the nylon filaments firmly in place.

We upgraded our equipment and refined the process through multiple trial runs. After several rounds of testing, we successfully produced an Inside Disk Brush that fully matched Mr. M’s requirements.

The Results

Impressed with the solution, Mr. M immediately placed a full-year order of 2,000 pieces. One month later, after installing and using the brushes, he shared his feedback:

“The bristles are strong, the backing holds its shape, and the brushes last much longer than expected. These brushes have significantly reduced our production costs.”

leave a message

Scan to Wechat :

Scan to WhatsApp :