In rolling mills, brush is necessary for metal surface treatment, such as cleaning, washing, polishing and deburring.

3 main factors that affect rolling mills brush selection for rolling mills are filament material, brush construction and working condition.

- Nylon Filament

Hard nylon is for strong cleaning. On the contrary, soft nylon is needed during fine cleaning. Advantage for nylon filament is acid-resistant and heat-resistant

- Abrasive Filament

Abrasive filament is nylon(PA6, PA612) mixed with abrasive materials. Diameter is from 0.46 to 1.78mm, and grit sizes are from 60# to 1000#. Grit size is higher, polishing performance is finer.

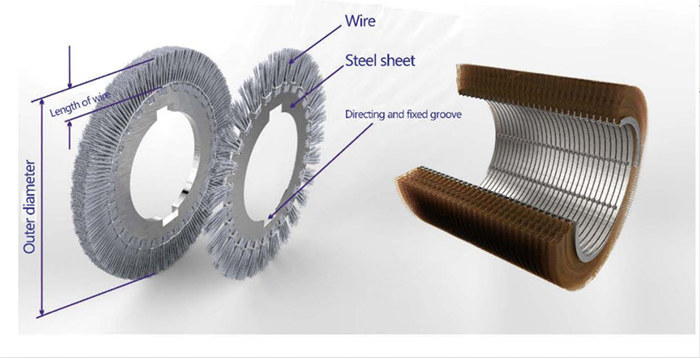

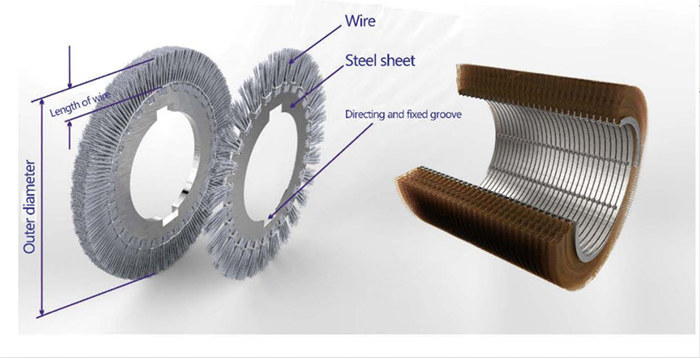

- Brush Outer Diameter

A larger outer diameter allows the roller brush to handle heavier workloads. The diameter can be customized according to machine size and rotating speed.

- Filament Working Length

This parameter depend on brush life time and machine size

- Adding Filament

There are two common filament arrangements: cassette type and spiral type. Accordingly, brushes are classified as cassette roller brushes and spiral roller brushes. In some applications, twisted in wire brushes structures are also used for stronger surface treatment and durability.

- Rotating Speed(rpm)

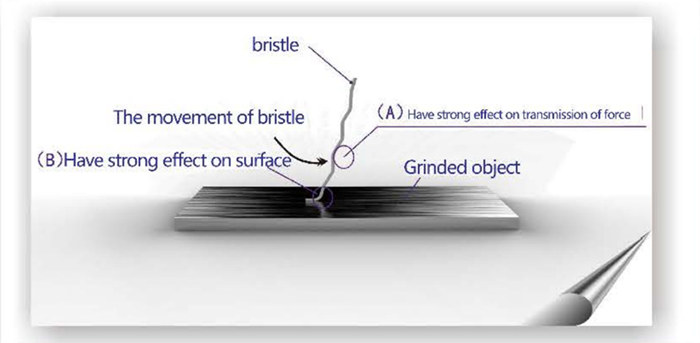

When setting rotating speed, it is necessary to give a full play to cleaning performance and polishing performance

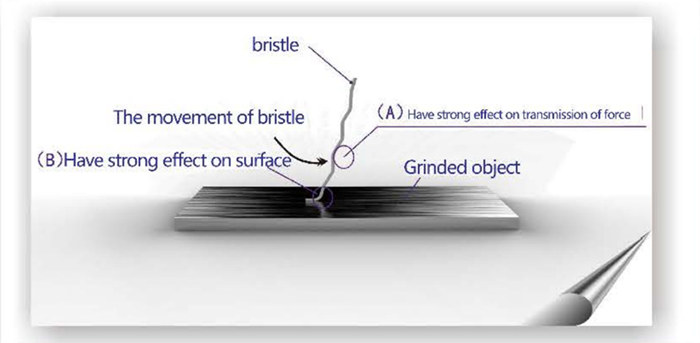

- Pressure(A)

- Spray On Brush

When brush is contacted with metal surface, the temperature is keeping rising. Spray bring temperature reduction. Spray in right direction remove dirt and increase cleaning performance. No spray will largely reduce service life of brush for rolling mills

If you would like to learn more, please visit our website:www.bajiebrush.com